Emulsifying ・ Mixing

General knowledge of emulsification technology

[Emulsification]

Emulsion is a form of mixture of two immiscible liquids in that one liquid is dispersed as fine droplets

in the other. This emulsifying technology is applied to many manufacturing fields such as cosmetics,

pharmaceuticals, food, agrichemicals and chemicals.

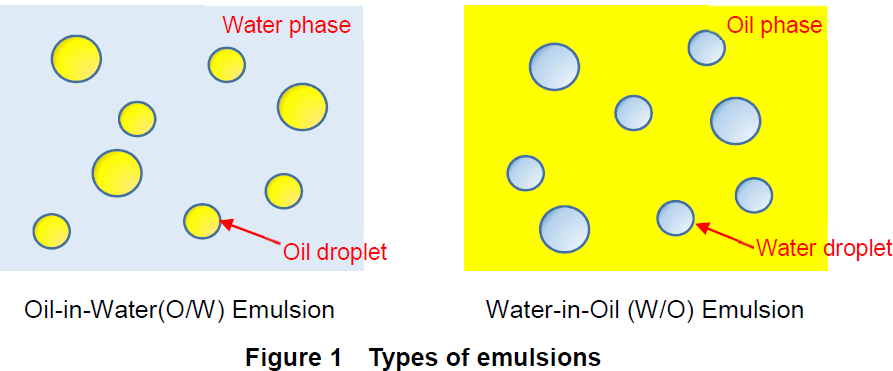

Types of emulsions are roughly classified into two: oil-in-water (O/W) and water-in-oil (W/O)

emulsions.

Emulsion products being familiar to our daily life are presented in Table 1 and are classified into the O/W and W/O emulsions. Characters of the emulsions are also presented in Table 1.

| O/W Emulsion | W/O Emulsion | |

|---|---|---|

| Examples of product |

Cosmetics: Skin milk & Cream, etc. Foods: Mayonnaise, Ice-cream, etc. |

Cosmetics: Hand cream, etc. Foods: Butter, Margarine, etc. |

| Characters | ・ Conductive ・ Easy to disperse in water ・ Feeling smooth |

・ Non-conductive ・ Hard to disperse in water ・ Feeling sticky |

[Conditioning ~Surfactant~]

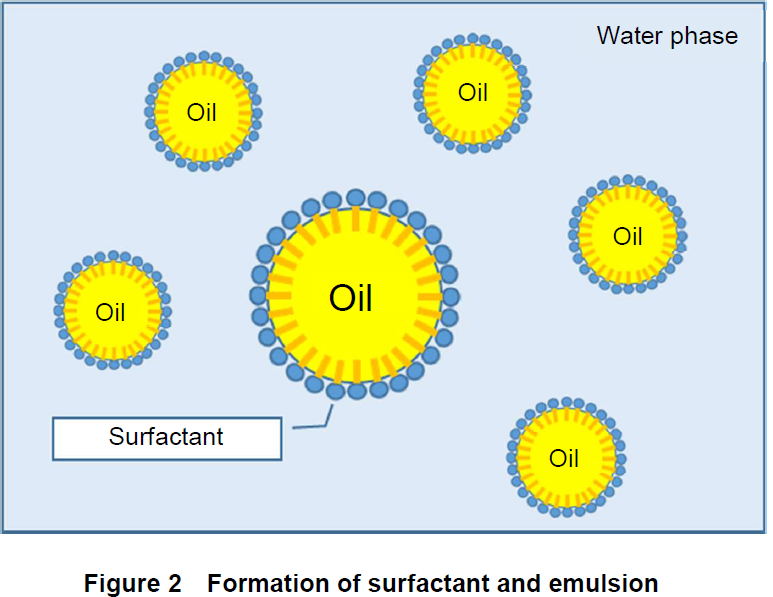

Interface between fine droplets and base liquid in emulsion is usually very activated and unstable.

Therefore, the state of emulsion is unstable. The droplets in the emulsion easily get together forming

larger droplets, and finally, two separated liquid phases are formed.

To prevent such deterioration of the emulsion, a surfactant (emulsifier) having both hydrophilic and

lipophilic characteristics is added in the liquids. The emulsifier added in the emulsion presents on the

interface of the two liquid phases and stabilizes the droplets.

Temperature control is an important technique for determining the quality of the emulsion when a

surfactant is used. Since the surfactant temperature ought to be controlled for the surfactant to

dissolve in a liquid phase, a temperature profile control during and/or after processing affects stability

of the emulsion in some case.

General knowledge of emulsifying equipment

The mainstream of industrial methods of emulsion production is a method of mechanically applying

shear force to two phase fluid. The shear force tears a liquid making minute droplets that are mixed

in the other liquid.

Various emulsifying apparatuses, such as high-speed stirrer typified by Homomixer, Ultrasonic

Homogenizer, and High-pressure Homogenizer, are used for processing. These emulsifying

apparatuses are explained below.

[Rotary-type agitating machine]

This is an apparatus that utilizes versatile mechanical agitation by a combination of a rotating shaft

and blades (i.e., stirring wings). Propeller mixer, Homomixer, and Disperser are sorted in this category.

The emulsifying kettle is a batch apparatus that has an integrated tank and stirrers. It is used for

production in many emulsion products. Although emulsifying apparatuses of this type are widely

applied, they are essentially batch processes and are not preferable to continuous processing.

[Ultrasonic homogenizer]

This is an apparatus to promote emulsification by utilizing “ultrasonic cavitation.” Since the

cavitation tends to exist locally in this method, the shear force is unevenly distributed in the tank, even

though the shear force is intense near the vibrator. Thus, the unevenly distributed shear force results

in an inhomogeneous emulsion in a large-scale tank. There is a difficulty in scaling up from a

laboratory work to a commercial-scale production.

Outline of “Apex Disperser ZERO”

“Apex Disperser ZERO (ADZ)” is a newly developed dispersing apparatus with a rotor in a cylindrical vessel. ADZ is applicable to dispersing submicron particles and nanofibers, mixing liquidpowder or liquid-liquid mixtures, and emulsifying a two liquid phase fluid. Note that Apex Disperser ZERO is named after “zero media disperser” since ADZ uses no grinding media.

[Structure overview]

ADZ has a rotor and a stator that form a round side wall of the vessel. The gap between the rotor

and the stator forms a narrowed gap. The gap geometry and rotation of the rotor make a steep

gradient of the fluid speed in the gap, and thus a high shear force is generated in the fluid. In addition,

surfaces of the rotor and the stator have textures to gain higher shear force.

An important feature of ADZ is that all the fluid passes through the gap during a single pass. Thus,

the shear force is uniformly acted on the fluid so that a uniform emulsion is produced even with a

single-pass processing. The time required for processing slurry by ADZ is several seconds or tens of

seconds.

ADZ has a capability of processing a high viscous fluid. Since the fluid is pushed upward with a

pressure comparable for resistance determined by viscosity of the fluid, the vessel can resist the

pressure. The viscosity acceptable is as high as 40,000 mPaS.

Feature and Benefit of APEX Disperser ZERO

(1) Single-pass processing

As described above, all the fluid fed into ADZ receives the shear force with geometrically even

distribution in the gap, a homogeneous emulsion is produced even in single-pass processing. Thus,

it is possible to shorten processing time and to downsize machines.

Particularly in case of processing a high viscous fluid, ADZ is advantageous for homogeneous

emulsion production compared to a batch-type emulsifying kettle, which requires hours to make a

homogeneous emulsion because of its geometrically uneven stirring in the tank.

[Practical example]

The figure below shows the relationship between flow rate of the fluid and droplet diameter in singlepass

processing by a test apparatus (Type ZERO-7).

By changing the fluid flow rate (or resident time), the droplet diameter can be controlled. The

achieved diameter of the droplets was one to 2 micrometers by single-pass processing.

Skin milk that is commercially available (cosmetic material) is an emulsion with droplet diameter of

several micrometers. ADZ, thus, produces an emulsion with the same or higher quality with singlepass

processing, suggesting that it is applicable to a continuous emulsifying processing plant.

(2) Applying to processing various viscosity and droplet diameter with no part change

ADZ has the capability of producing various kinds of products by changing operating conditions

without replacing its mechanical parts. For example, a single unit of ADZ has an ability to produce

skin milk with low viscosity and hand cream with 40,000 mPaS.*1

It is also possible to produce skin milk or cream having droplet diameter of submicron to several

micrometers by only adjusting rotational speed of the rotor and fluid feed rate (or resident time). Since

ADZ is applicable to processing emulsions with different properties, it is an ideal apparatus for

laboratory works researching on new products and is suitable for small rot productions.

*1 viscosity measured by Cone-plate viscometer

[Practical example]

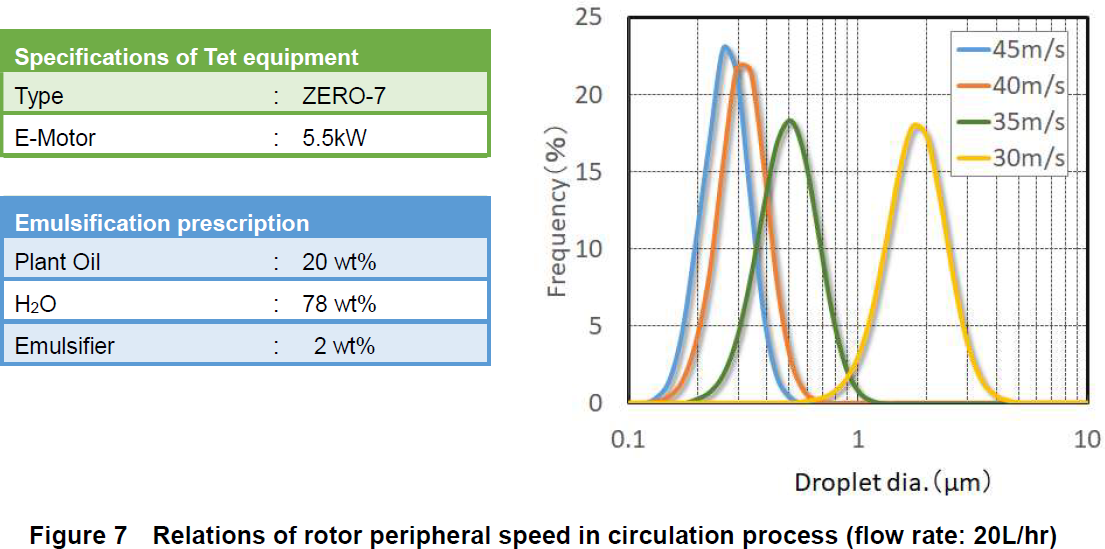

Figure 7 shows the relationship between rotational speed and droplet diameter in circulating

(multi-pass) operation using Type ZERO-7. It is observed that the droplet diameter of emulsion can

be controlled by changing the rotational speed. Emulsion with smaller droplets was produced at a

higher rotational speed. At the highest speed, 45 m/s, the droplet size was 250 nanometers. This

emulsion has a good resistance against flotation of oil droplets (creaming).

(3) Variations of operation

ADZ provides several operational options of fluid feeding methods and apparatus configurations of emulsifying or dispersing plants. The following three operational options, for example, are available: (a)multiple fluid feeding, (b) single-pass processing, and (c) circulation feeding processing.

- (a) Multiple fluid feeding

- Since ADZ has a mixing function, two or more fluids are independently fed into the ADZ vessel

to produce an emulsion of these fluids. Water phase and oil phase fluids, for example, are fed

from two inlets at the bottom of the vessel. They are mixed while they are traveling in the pass

between the bottom and the rotor and then the mixture is emulsified in the gap between the rotor

and the stator.

The multiple fluid feed operation makes an emulsion processing plant simplified. The process configuration proposed is of two feeding tanks (water phase and oil phase liquids), two slurry pumps, and ADZ, in which a mixing tank and a pump are avoided. - (b) Single-pass processing

- Since all the liquid fed into the vessel travels through the gap where the shear force acts on

the liquid evenly, it is possible to produce a homogeneous emulsion even with a single-pass

processing.

Slurry emulsified by ADZ can directly be sent to a next processing step for making emulsion products. Thus, ADZ provides a continuous production plant of emulsified products, that is, a combination of feeding tanks, ADZ, and after-treatment apparatuses. The emulsion processed by the single-pass operation of ADZ has the quality equivalent to commercially available skin milk having a droplet diameter of micrometers. Emulsion products of the same or higher quantity are processed by the circulation operation by ADZ than by other types of apparatuses.

Since ADZ with a single-pass processing mode is hooked up directly a post-processing process, ADZ provides a closed processing system connecting material feeding tanks, ADZ, a de-foaming machine, and a bottling machine with a closed pipe system. With this closed system, we can avoid the cumbersome operation caused by the batch operation, prevent contamination of foreign matters, and improve the working environment. - (c) Circulation processing (multi-pass processing)

- In the circulation processing, it is possible to produce emulsions with the droplet diameter 250 nanometers to bigger than 10 micrometers. With ADZ, since the droplet diameter is simply

determined by controlling the rotor speed and the processing time (or flow rate), it is possible to

produce various kind of products with a single unit of ADZ. No mechanical part change is needed.

In addition, temperature of the fluid in the vessel is controlled by the temperature of water passing through the stator’s jacket and rotational speed of the rotor. Thus, when water with adequate temperature is fed in the stator’s jacket, emulsifying processing that needs temperature control (60–80℃ or 140–200°F) is performed easily. Furthermore, by switching the hot water to the cooling water, it is possible to cool the hot emulsion. Applying this method, a single unit of ADZ provides the stepwise heating and cooling.

(4) Easy disassembly and quick cleanable design

Since ADZ consists of a small number of mechanical parts and its structure is simple, it is easy to disassemble and reassemble the apparatus, and therefore easy to clean the parts. In addition, ADZ is applicable to “soaking and cleaning” and non-disassembly CIP (Clean in Place), for sanitary requirements.

(5) R&D apparatus for researching emulsifying, mixing, and dispersing

ADZ is simply structured, and it produces various products from various raw materials only by

controlling the operating conditions. Research works for developing various kinds of emulsion

products can be done by a unit of ADZ alone.

In addition, it is easier to scale up the ADZ machine than other processes, as the kettle

processes. It is because all the fluid fed in the vessel receives uniform shear force even in a much

larger unit. On the other hand, there is geometrical dead space in the vessel of most of the batch

processes. Scaling up these processes is much tougher.

Furthermore, since ADZ is utilized not only for emulsification but also for various purposes,

such as “low damage dispersion,” “mixing viscous materials,” “mixing fibrous materials,” and “defabricating

nanofibers.” Thus, ADZ is an ideal apparatus for scientists researching on “slurry.”

[References]

1) Basic of Modern Colloid and Interface Chemistry Chemical Society of Japan

2) Adjustment Technique of Emulsion collection of cases Technical Information Institute Co., Ltd.

3) New Cosmetology Second Edition NANZANDO Co., Ltd.