遠心分離Wizard Press / WP

The latest centrifuge that can reduce sludge disposal costs and operation management costs!

Overview

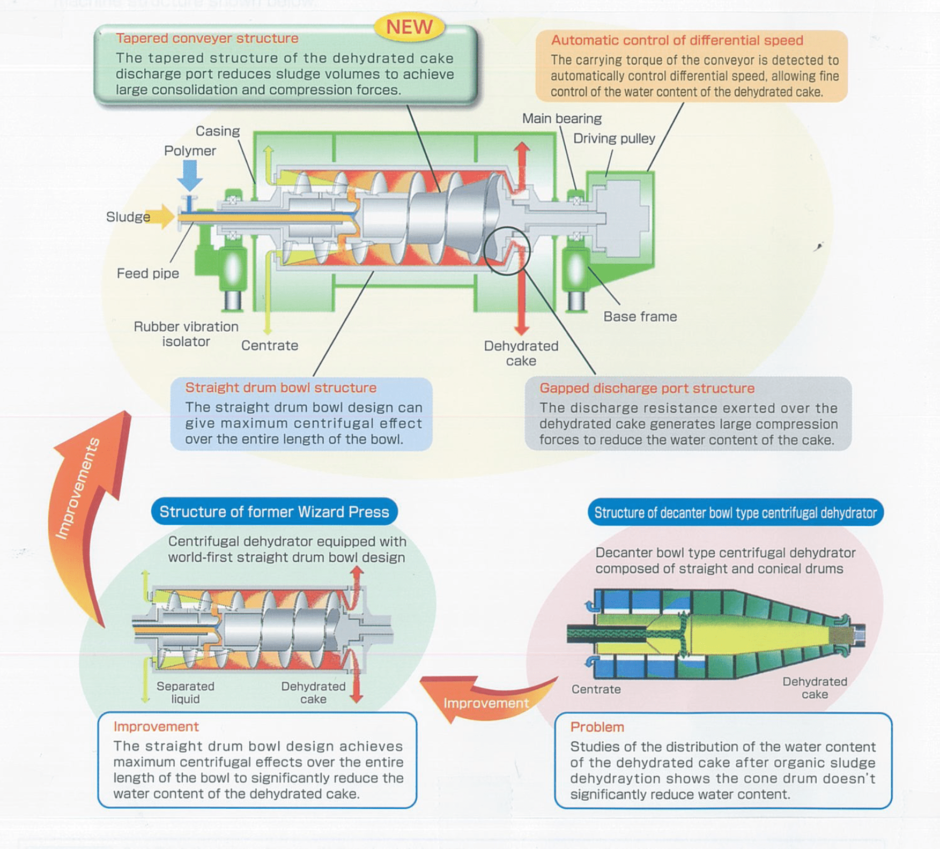

Wizard Press™ is a high performance centrifugal dehydrator for organic sludges with unique structures. It employs a straight cylindrical bowl to improve in decrease in the centrifugal force near the cake discharging end of the bowl, which is a disadvantage of the conventional centrifugal dehydrator equipped with a tapered bowl. Arrangement of the bowl and the conveyer is designed to provide a uniform, thick cake layer from the slurry inlet to the cake discharging end. The combination of the thick cake layer and the straight bowl maximizes the centrifugal effect.

In addition, the cake receives compaction in the discharging gaps by adopting the unique structure of the discharging parts. As a result, the cake is further dewatered in the gap. Thus, this centrifugal dehydrator is ideal for dewatering organic sludges.

Thanks to the advanced features of this model, organic slurries are more efficiently dehydrated than the conventional ones. Thus, it is possible to reduce mass of the dehydrated cake and to make the separated water more clarified at the same time. Thus, the treatment cost and the risk of contamination of the wastewater are reduced.

In addition, when this model is applied to liquid-solid separation processes of the food and beverage industries, the yield of the feedstock is improved, and the production cost is reduced.

Features

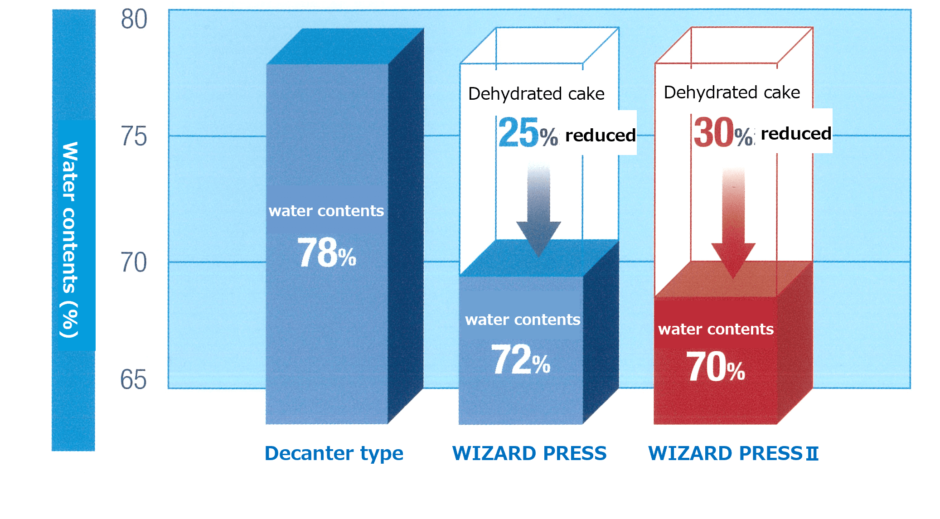

- 1.Low moisture content operation; reducing cake disposal costs

- As Wizard Press yields dehydrated cakes with lower water contents than the conventional decanters, the sludge disposal cost is significantly reduced in the wastewater treatment process. In addition, if a dryer or a carbonization furnace is installed in the subsequent stage, energy for the processing is saved, and the equipment is downsized.

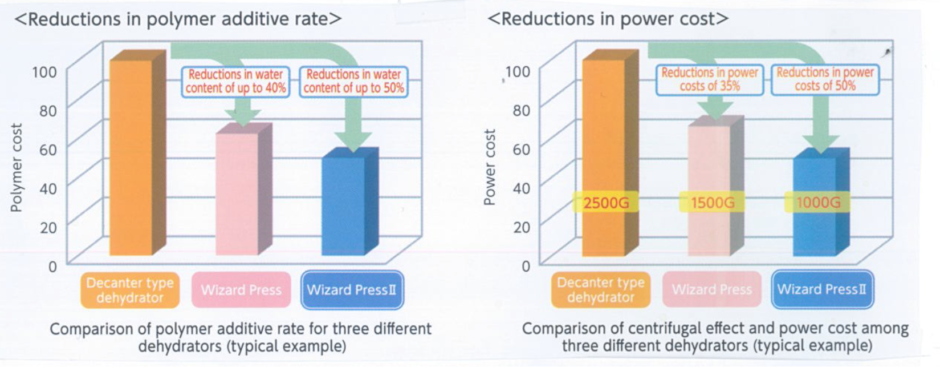

- 2.Low cost operation; Reduces power and additive chemical costs

- Wizard Press saves operational costs when the same water contents of the dehydrated cakes as the conventional decanters is required.

Case 1: Lower centrifugal force is applied for saving the power consumption, or Case 2: the addition rate of the flocculant is reduced.

- 3.Unmanned and labor-saving operation; Automatic control responding changes in properties of the slurries

- Wizard Press is equipped with an auto control system for constant water content of the cake. The differential speed between the conveyor and the bowl is automatically controlled by detecting the torque acting on the conveyor. Thus, unmanned operation is available. Even in case that properties of the slurry changes, the water content of the dehydrated cake is controlled to be constant at the target value. In addition, it has an automatic shutdown mode. The internal parts of the machine are firstly washed and then the machine sequentially stops. When stopping the machine, an operator just presses ‘STOP BOTTAN’, so the stopping operation is easy, and no cumbersome washing task is needed.

Structure of Wizard Press

Slurry is supplied into the machine via a feed pipe and mixed with polymer flocculant in the chamber of the screw conveyor to form coagulating flocs. Then it enters the space between the bowl and the conveyor. The flocculated slurry is efficiently dehydrated by the unique structures shown in the following figure.

Applications

| Food stuff | Wastewater |

|---|---|

| ・Soy milk | ・Sewage sludge / mixed sludge |

| ・Crushed corn dregs | ・Manure / sludge regeneration treatment sludge |

| ・Whiskey distilled residues (feedstock recovery) | ・Food residue digested sludge / biomass power generation |

| ・Sake, beer, and spirits brewing wastewater / excess sludge, digested sludge |

Standard Specifications

| Model | Capacity (㎥/h) |

Drive motor kW | Centrifugal effect (G) |

Weight (kg) |

Approx.Dimensions (mm) |

|||

|---|---|---|---|---|---|---|---|---|

| Main | Differential | L | W | H | ||||

| WPⅡ200 | 0.5 〜 1 | 3.7 | 3.7 | 2500 | 500 | 1750 | 1000 | 600 |

| WPⅡ500 | 1 〜 3 | 5.5 〜 7.5 | 3.7 | 2500 | 710 | 2050 | 1030 | 660 |

| WPⅡ700 | 3 〜 5 | 7.5 〜 11 | 5.5 | 2500 | 1500 | 2460 | 1350 | 720 |

| WPⅡ1000 | 5 〜 7 | 11 〜 15 | 5.5 | 2500 | 1900 | 2910 | 1485 | 945 |

| WPⅡ1250 | 7 〜 10 | 15 〜 18.5 | 7.5 〜 11 | 2500 | 2300 | 3075 | 1645 | 1010 |

| WPⅡ1500 | 10 〜 15 | 18.5 〜 30 | 7.5 〜 11 | 2500 | 2600 | 3265 | 1645 | 1010 |

| WPⅡ2500 | 15 〜 25 | 37 〜 45 | 11 〜 15 | 2500 | 3800 | 3810 | 2130 | 1150 |

| WPⅡ3500 | 25 〜 35 | 55 〜 75 | 30 | 2500 | 7500 | 4700 | 2320 | 1400 |

| WPⅡ4500 | 35 〜 45 | 75 〜 90 | 30 | 2500 | 10500 | 5380 | 2520 | 1480 |

| WPⅡ6000 | 45 〜 60 | 132 | 37 | 2000 | 16250 | 5540 | 2700 | 1450 |

| WPⅡ8000 | 60 〜 80 | 160 | 45 | 2000 | 21000 | 6510 | 2310 | 1870 |