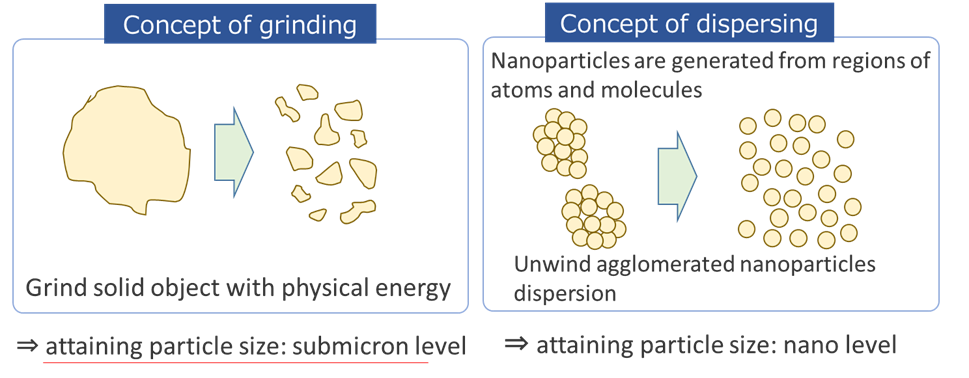

Grinding/DispersingUltra Apex Mill / UAM

Standard model applicable to treatment with micro-beads, minimum size 15μm in dia., for nanoparticle grinding and dispersion.

Overview

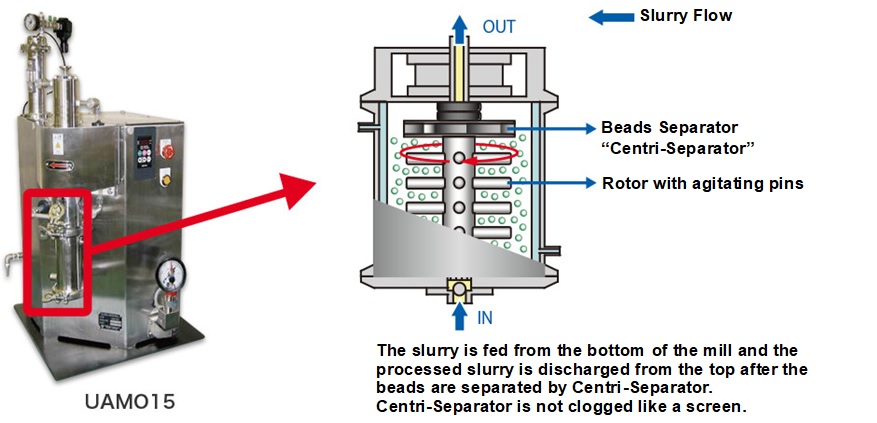

Adopting a centrifugal separator for bead separation, the first in the world, this micro-bead mill can use beads of Φ15μm to 1 mm.

Processing using microbeads of Φ0.1mm or smaller provides dispersion of slurry containing fine particles of 100nm or finer, such as fine inorganic powders, for example crude material of ceramics, electromagnetic materials, optical materials, etc. and pigments.

Among our bead mills, this model is the most widely applicable nanoparticle disperser; we have conducted several improvements on this model for widening its applications in these 20 years. This is the most suitable bead mill for dispersion processing submicron to nano-sized particles in general use.

It contributes to the technical progresses in the nanoparticle processing of barium titanate, organic chelate pigment, liquid crystalline coating agent, etc.

This bead mill can also be used for grinding of submicron to nano-sized materials since relatively large beads of Φ0.5 to 1mm can be used, thus this is a multirole bead mill.

We also have sold units of this model for grinding API pharmaceutical crude chemicals of 200 nm or less.

By inventing a micro bead separator utilizing centrifugal force, the first in the world, we have been awarded “Award for Prominent Master of the Manufacturing” and “the Science and Technology Award for Invention” from the Japanese Government.

Features

- 1.Microbeads are available for dispersing and grinding submicron to nano particle with this model!

- UAM is capable of dispersing slurry of nanoparticles with a minimum diameter of 20nm because it can use microbeads with a minimum diameter of 15 μm. UAM has a structure of the agitating rotor with high dispersion force so that it has a high processing capacity.

- 2.Small and large beads are available to process multiple kinds of slurries in one unit!

- UAM handles a wide range of bead diameters from φ15 μm to φ1mm. As it has a centrifugal bead separator, even if beads of different diameters are used, any mechanical adjustment is not necessary. Multiple kinds of slurries, such as pre-processing (large beads) and finishing dispersion (fine beads), are processed in a series without changing any mechanical part.

- 3.Easy disassembling and assembling, and easy slurry recovery!

- Since it is a vertical bead mill and simply designed, it is easy to disassemble and assemble. It is also easy to recover slurry left in the mill.

- 4.Cleanability is also considered!

- Some versions of this model have improved cleanability for applications with high hygienic requirements, such as food, cosmetics, and pharmaceuticals by redesigning shape and packing of corners and joints of the bead mill.

Structure

Operating condition

- Applicable bead diameter

- Φ15μm〜Φ1mm

- Bead separator circumferential speed

- 8m/s〜12m/s

Application and final product examples

| Material | Application | Objective of Dispersing | Attainable Particle Size (nm) |

|---|---|---|---|

| Organic pigment | Liquid crystal pigment | Pulverization, Transparentizing, Granularity stabilization | 15 |

| Ink-jet pigment | Pulverization | 50 | |

| Zinc oxide | UV care cosmetics | Pulverization, Transparentizing | 10 |

| Alumina | Abrasive, Filler | Pulverization | 15 |

| Hard coat for plastics | Hardness enhancer | 10 | |

| Silica | Wafer abrasive | Pulverization, Particle size homogenization | 10 |

| Polymar composite | Strength improvement, Transparency improvement | 10 | |

| ITO,ATO | Transparent electrode, Heat ray absorbing film |

Electric conductivity, Transparency improvement | 40 |

| Anti-reflective coating film | |||

| Battery material | Cathode material, Anode material | High power, High capacity, High quality | 20~5,000 |

| Separator, Conductive assistant | Pulverization | ||

| Nano silver | Light shielding material Conductive material | Light shielding performance improvement, Electric conductivity | 20~50 |

Main specification of the Ultra Apex Mill.

| Model | Inner Volume (L) |

Drive Motor (kW) |

Approx. Dimensions (m) | Approx. Weight (kg) |

||

|---|---|---|---|---|---|---|

| Length (m) |

Width (m) |

Height (m) |

||||

| UAM-015 | 0.15 | 2.2 | 0.6 | 0.48 | 0.85 | 100 |

| UAM-05 | 0.5 | 3.7 | 1.10 | 0.65 | 1.40 | 200 |

| UAM-1 | 1 | 5.5 | 1.10 | 0.80 | 1.75 | 350 |

| UAM-2 | 2 | 7.5 | 1.10 | 0.80 | 2.10 | 450 |

| UAM-5 | 5 | 15 | 1.25 | 0.80 | 2.10 | 550 |

| UAM-10 | 10 | 22 | 1.40 | 0.85 | 2.20 | 700 |

| UAM-30 | 30 | 55 | 2.10 | 1.45 | 3.00 | 2700 |

Lineup of Apex Mill Series

| Products | Summary | Applicable beads size |

|---|---|---|

| Apex Mill | Bead mill for grinding Vertical type bead mill for grinding particles of micron to submicron. |

φ0.3mm~φ5mm |

| Ultra Apex Mill | World`s first microbead mill Standard model of microbead mills for nano-grinding and nano-dispersion using microbeads, min. dia. 0.015mm |

φ15μm~φ1mm |

| Dual Apex Mill | Biaxial microbead mill This microbead mill is sued for nano-dispersion especially with low crystal damage. |

φ15μm~φ1mm |

| Wide Separator Apex Mill | Bead mill capable for high flow rate and with highly viscous slurry Microbead mill capable for dispersion nanoparticles at a high flow rate and/or with high viscosity. |

φ15μm~φ0.3mm |

| Ultra Apex Mill Advance | Ultimate low damage nano disperser Microbead mill providing a proper condition for nano dispersion with super low crystal damage. |

φ15μm~φ0.3mm |